Keys to success: Merchandise Planning and the open-to-buy formula

In the retail business there really is one goal at the end of the day: sell merchandise at a profit. Regardless of the price point, uniqueness of the product or target market, it’s in your company’s best interest to get those items into the hands of consumers – with the objective of maximizing profitability.

In order to accomplish this objective, proper managing of said merchandise is key. Having an efficient and strategic merchandise plan can effectively transform the way your company is able to sell products; it enables you to see areas that may need improving and allows you to be more flexible in times of market uncertainty. An effective merchandise plan needs a solid Open-to-Buy (OTB) system – in essence a formula to manage anticipated inventory flows and levels. Determining the best OTB formula for your merchandise strategy is imperative as too much inventory means high markdowns and a poor return on investment, whereas too little means missed sales.

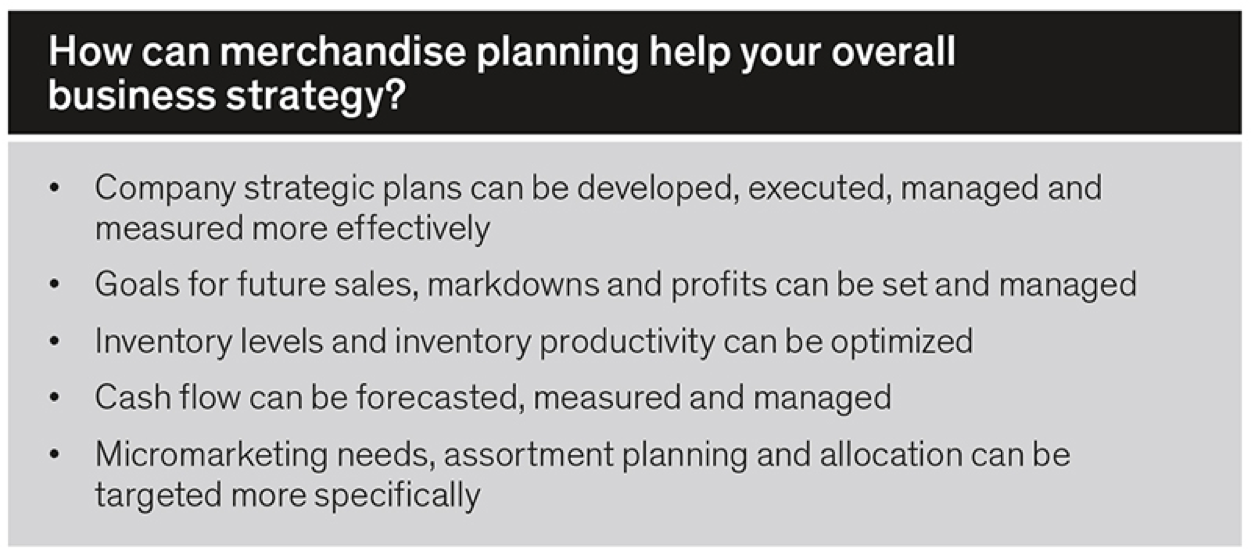

Merchandise planning can fine-tune your OTB formula, and if done effectively, can also:

• drive profitable sales;

• maximize inventory turns; and

• enhance gross margins (which in turn increase operating profits and cash flow).

Implementing a merchandise plan not only helps your business in terms of sales, but it can also lay the groundwork for strategies that can further fine-tune how you do business overall.

The benefits of employing such a plan are many; therefore the process of planning and implementing must be thorough, disciplined and focused. Ultimately, you want to ensure you have the right merchandise, in the right quantities at the right time, marked with the right price. Doing so will help ensure that the largest asset on your balance sheet – your inventory – is optimized.

The steps to maximizing inventory productivity

You should ultimately implement a plan before the buying process is started – this is as crucial as establishing a proper financial plan from the outset. Create a merchandise plan before any (more) purchases are made, ensure proper steps are taken for implementation and continually evaluate to ensure you’re on the right track.

Before you begin crafting a plan, be sure to consider the following:

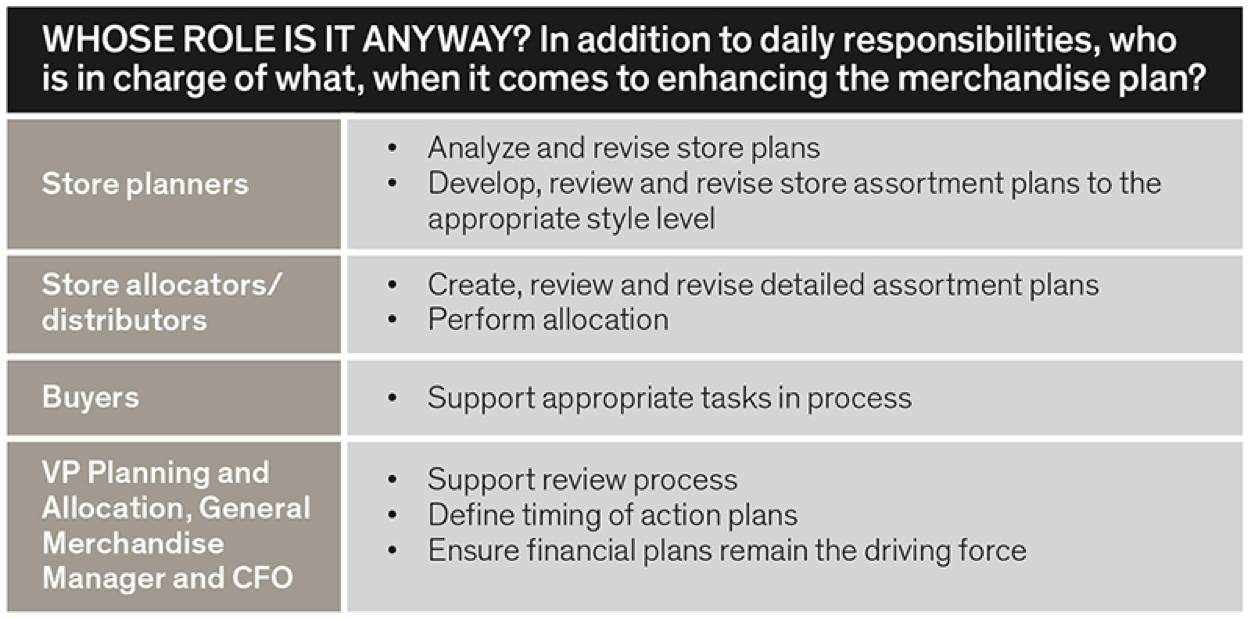

- Organization and responsibilities

Consider your organizational chart to be just as important as your financial plan in order to maximize inventory productivity. Creating a merchandise plan is a team effort. Many different departments should be included in this collaboration from buyers to general merchandise managers so the plan is thorough and not only managed top-down, but supported from the most local and specific roles, as well.

When establishing this structure, think of it as a hierarchy. Consider all the different moving pieces from the VP of planning to the divisional planning manager, the merchandise controller, the store planner and the distributor. It’s imperative to delegate a senior executive as head of planning and allocation to ensure proper oversight and project management. Be sure to clearly define all roles, responsibilities and core competencies for each position and make each objective clear to all.

It’s important to note that planners and buyers should have equal status when it comes to merchandise planning. When implementing the plan, also be sure to consider the ratio of a) buyers to planners, and b) buyers to distribution analysts.

- Planning calendar

As the planning process should begin prior to acquiring merchandise, consider the length of time it will take to complete each step including overseas procurement, domestic procurement and selling timeframe. Considering the hierarchy is also key in this instance: include input and approval from each division and department, and account for different units and store-level implementation which may extend the length of time required. It can be time-consuming, but this is crucial to ensuring the process is all-encompassing, well thought out and effective.

Proper logistical support to the replenishment of core inventory is critical. Be sure to consider the following variables that may also affect timing:

- seasonal changes;

• merchandise management and reporting systems;

• assortment planning; and

• distribution and space planning.

- Assortment plans and space planning

Creating and monitoring assortment plans is key to keeping the planning system current and effective. Up-date assortment plans and schedule pre- and in-season reviews to keep everything organized and in check. Maintain a monthly or bi-weekly ledger of notes with specific details so monthly and seasonal reviews are easier to recap. Detail what may have affected sales that month and why it may or may not happen again next year – was April a particularly cold and rainy month? Perhaps that was the reason why sales were lower for that period.

It’s also important to account for the sales per square foot and gross margin per square foot when planning. The sales per square footage ratio is a great way to compare store performance and can be a key indicator when evaluating not only what is selling, but also what’s NOT selling. Pinpointing items that are either not in the right location, or are just not selling at all, and re-evaluating how much of this merchandise is being bought, can save you significant dollars. At the micro-level, comparing store-by-store performance can help indicate which inventory should go to which location. This also correlates to how much inventory you will need, and therefore how many times you will need to turn it, whether your gross margins are close to your goals, how much stock you should have on hand for each week and whether or not your rate of sale is hitting your inventory targets.

Once you’ve established the groundwork for the planning process, start to enhance and finetune the plan. Reconcile merchandise, store, and financial plans. Evaluate contingency and alternate plans – consistently ask “what if” to ensure your strategies are solid – i.e. what if terrible weather affects a port and your shipment is delayed?

Also continue focusing on building relationships, and communicating roles and responsibilities of the merchandise team, store operations and finance teams so they can be fully collaborative. Organize the feedback structure so everyone involved has a hand in enhancing the plan as well.

Analyze the strategy and evaluate where cohesions exist and where they diverge – seek to blend the bottom-up and top-down planning as well as the dollar and unit planning to be fully collaborative.

Software tools to assist your team

There are several interesting and beneficial software planning systems that may be able to help enhance your strategy. They include:

- SAP;

• Epicor;

• Gemmar;

• Maple Lake;

• Buyers Tool Box (ANT USA);

• Retek;

• QlikView; or

• don’t forget, good old faithful Excel!

However, these systems are not one-size-fits-all and different software may offer different solutions. Finding the right fit for your specific needs is key.

Above all, implementing a merchandise plan is an evolutionary process, not an immediately revolutionary break through. In the long run, effective merchandise planning can save you time, help streamline your business processes and objectives, and optimize and mobilize your

inventory to get it off your shelves and into the hands of your consumers for the right price.

About Richter : Founded in Montreal in 1926, Richter is a licensed public accounting firm that provides assurance, tax and wealth management services, as well as financial advisory services in the areas of organizational restructuring and insolvency, business valuation, corporate finance, litigation support, and forensic accounting. Our commitment to excellence, our in-depth understanding of financial issues and our practical problem-solving methods have positioned us as one of the most important independent accounting, organizational advisory and consulting firms in the country. Richter has offices in both Toronto and Montreal. Follow us on LinkedIn, Facebook, and Twitter.